Back

Which Firefighter Air Decontamination Technology is Best?

Posted on 6th November 2024

A Comparison of Gas Phase, Needlepoint Bipolar Ionization (NPBI™), and Photohydroionization® (PHI)

By now, you probably know that there are several types of air decontamination and filtration technologies available for firefighter apparatus and fire station protection. Gas Phase, Needlepoint Bipolar Ionization, and Photohydroionization are three prominent technologies in the firefighter air decontamination and filtration space. Below, we’ll discuss these three technologies, including the pros and cons of each. But first, let’s talk about airflow.

The Importance of Air Flow

Firefighting apparatus, ambulance, and fire station air decontamination products are only as good as the air flow that goes through them. Your air decontamination or filtration solution needs to have enough force to move air through any filters, media, or stage included in the unit with minimal blowback at the intake area. If air is not forced through adequately, it can escape through side vents or other openings rather than moving through these components. A filter is important in your air decon system so that it can capture and neutralize contaminants. If there is no filter, or the airflow does not sufficiently move air through the filter and other media, the air will not be properly cleaned. This means those contaminants will remain airborne and your crew will remain at risk.

It is also important that your system can work with a variety of airflow scenarios, like open windows or opening and closing bay doors. You know that fire stations and apparatus can be hectic places with doors and windows opening and closing regularly. If your system is interrupted by these elements, it will not do a good job mitigating disease and cancer-causing threats in the air.

Because airflow is so important to ensuring clean, healthy air, we encourage you to examine how each product you consider handles air movement.

Now, let’s dive into the advantages and disadvantages of different technologies.

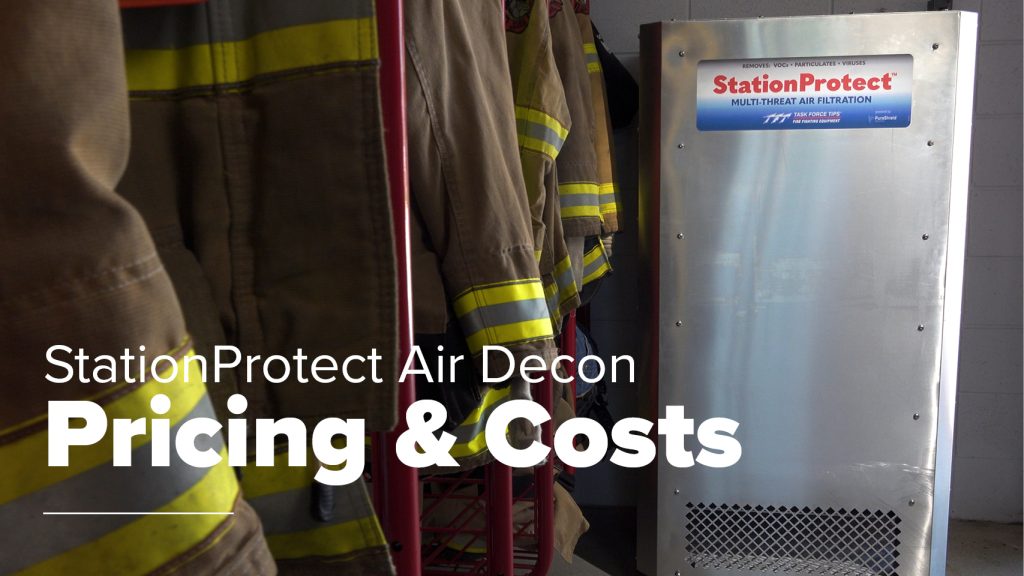

TFT Health Firefighting Air Decontamination

Gas Phase technology was developed to provide added protection from cancer-causing volatile organic compounds (VOCs). This technology is combined with pre-filters and HEPA filtration within separate stages to clean any air passing through. Gas Phase filtration is an established filtration technology that services NASA launch pads, the Smithsonian Institute, and more!

Gas Phase Advantages

The TFT Health filters use multiple stages to decontaminate the air. One of its main advantages is how thorough the system is when cleaning the air.

Preliminary Filtration

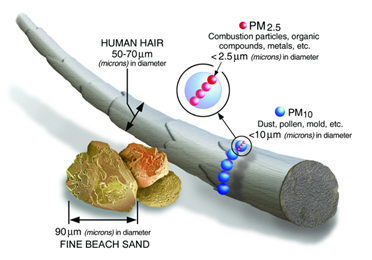

The prefilter collects larger particulate matter and carries a MERV 6/8 rating. This rating filters down to 3.0-10.0-micron particle size and reduces contaminants such as lint, cement dust, pollen, mold and spores, carpet fibers, sanding dust, dust mites, and many other large particulates commonly found in the air you breathe.

When it comes to your health and the health of your crew, it is critical that particulate matter is effectively filtered from the air. Particulate matter can contain microscopic solids or liquid droplets that can cause serious health problems over time. Some particles can get deep into your lungs, and some may even get into your bloodstream, potentially causing long-term health problems, diseases, and some cancers.

Gas Phase Filtration

The patented, spherical, porous pellets remove gaseous pollutants from the air through a unique chemical process known as chemisorption. During chemisorption, the media converts harmful gases from the air into harmless materials that are captured and bonded to the media pellets. These pellets also capture and neutralize odors.

HEPA Filtration

The final stage is a high-quality HEPA filter that further reduces particulates, allergens, and aerosols in the air. This level can capture smaller particulates (including PM0.3 and PM2.5) with 99.97% efficiency before releasing clean air back into your firefighting apparatus or fire station.

TFT Health Disadvantages

Consumable Parts

Some of the media within the Purafil system must be replaced at specified intervals to remain effective. This requirement means you need to buy and replace cartridges at these intervals to remain protected.

Needlepoint Bipolar Ionization (NPBI™)

Needlepoint Bipolar Ionization claims to clean indoor air by using an electronic charge to create a high concentration of positive and negative ions. These ions continuously travel through your apparatus cab or fire station seeking out and attaching to particles. This creates a continuous pattern of particle combination. As these particles become larger, they are removed from the air. They may fall out of the breathing zone or find their way into a filter found in your apparatus or fire station.

NPBI Advantages

Minimal Consumable Components

One advantage of NPBI filtration technology is the lack of consumable components. There are no bulbs, filters, or solutions to change in the unit. Many of the units that use this technology also claim to require minimal maintenance and cleaning over the life of the unit. Without much maintenance, your time commitment for upkeeping the system would be minimal.

Simple Installation

The NPBI technology typically comes in units that are easy to install in most fire apparatus or first responder vehicle cabs. The larger units are designed for fire stations and are easy for you to move around. Units intended for the vehicle or station are relatively unobtrusive as well.

NPBI Disadvantages

Insufficient Air Flow Volume

Some of the firefighting and first responder air decontamination units that are using NPBI often do not have ideal airflow across the technology. Some units that are built for larger volumes of air, like your fire station or gear room, have a large fan pushing air through the technology. However, the design does not allow all the air moved by the fan to go through this space. Instead, much of the air would be circulated around the filtration technology. This may lead to lower concentrations of positive and negative ions in the air.

No Filter

The NPBI technologies do not include a filter capable of capturing particulate matter or the compounds created by particle combination. This means that any particulates or compounds will remain in the air until they are heavy enough to fall to the surface or get captured in a filter. The system may also create new contaminants as particles combine. There is no way to control the combination process or what it produces. Additionally, there is no filter or other media to capture and neutralize these contaminants.

Photohydroionization (PHI) Filtration

Photohydroionization is an advanced oxidation technology that minimizes pollutants in the air through a broad-spectrum, high-intensity UV light. Low doses of airborne hydroperoxides are generated. These hydroperoxide molecules revert to oxygen and hydrogen once they encounter and mitigate a pollutant in your apparatus or fire station.

PHI Advantages

Effective Reduction of Airborne Pathogens

Systems using Photohydroionization technology are effective at reducing airborne pathogens. This includes SARS-CoV-2, and other viruses or bacteria that may cause illness. If your largest concern with air quality is neutralizing germs, microbes, viruses, and bacteria, PHI technology may be sufficient for your needs.

Surface Disinfection

Because PHI disperses hydroperoxides into the air, these molecules can travel and land on nearby surfaces. This can achieve disinfection on surfaces. You would still need to wipe surfaces regularly to remove dirt or particulate matter, but viruses and bacteria could be reduced with these technologies.

PHI Disadvantages

Does not Filter Fire Ground Contaminants

PHI technologies are good for mitigating pathogens, germs, microbes, bacteria, and viruses from the air. However, units using this technology do not have a filter and cannot reduce particulate matter in the air. Some units using this technology state that the devices do not filter for fire ground contaminants which is a critical piece of information for firefighters when evaluating these systems. If you are concerned with fire ground contaminants such as particulates, a PHI-based system would not be enough.

Consumable Parts

Systems that use Photohydroionization include consumable parts that need replaced at specific intervals. Each unit typically has a UV bulb and hydrated quad-metallic catalyst. After a specified amount of time, you would need to buy and replace these items to ensure the proper concentration of hydroperoxides in the air.

So, which technology is best?

Deciding which technology is best for your department can be a difficult decision. Remember to consider your goals and biggest concerns as you evaluate each system. If you are only concerned with viruses, bacteria, and microbes, you may not need one of the more robust systems. If you are worried about VOCs, particulates, and aerosols carrying viruses and bacteria, you will want a system capable of reliably mitigating each concern.

Let’s recap all three systems:

TFT Health

Has a multi-stage cartridge capable of mitigating VOCs, particulates, aerosols, and mold.

The cartridge system means there are consumable parts that must be replaced at specified intervals.

Needlepoint Bipolar Ionization

Does not have any consumable parts and requires minimal cleaning and maintenance.

Air flow may not be reliable and there is no filter to capture particulates.

Can create harmful byproducts that add to air contamination.

Photohydroionization

Photohydroionization

Does not filter fire ground contaminants or particulates, including VOCs.